Understanding the Differences between Forged and Cast Soft Seat Ball Valves

When choosing the right ball valve for your industrial application, it is critical to understand the difference between a forged soft-seated ball valve and a cast soft-seated ball valve. The manufacturing processes and performance characteristics of these two types of ball valves are different, and these factors must be considered when selecting.

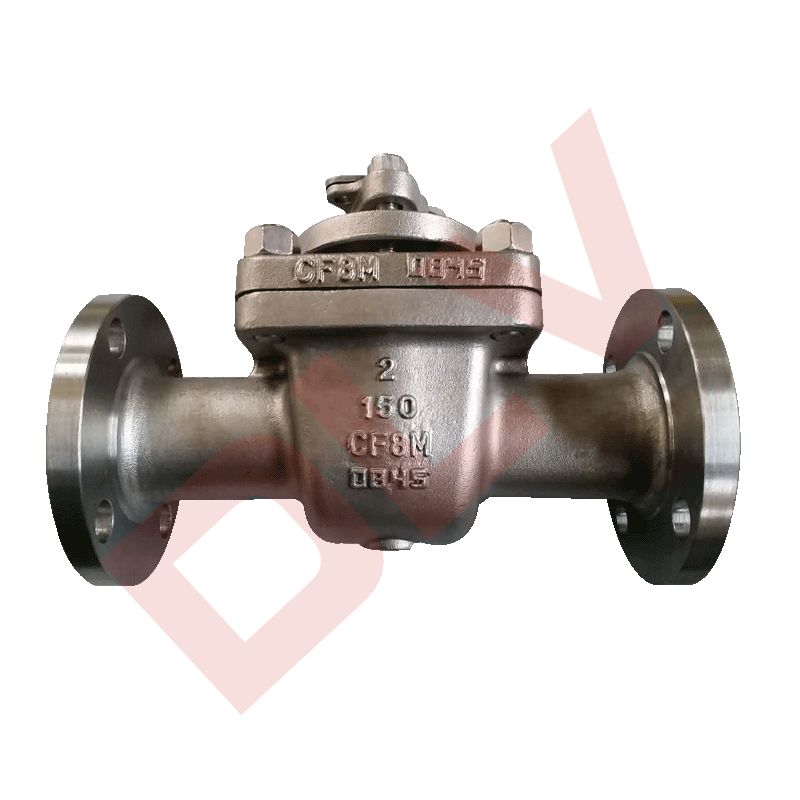

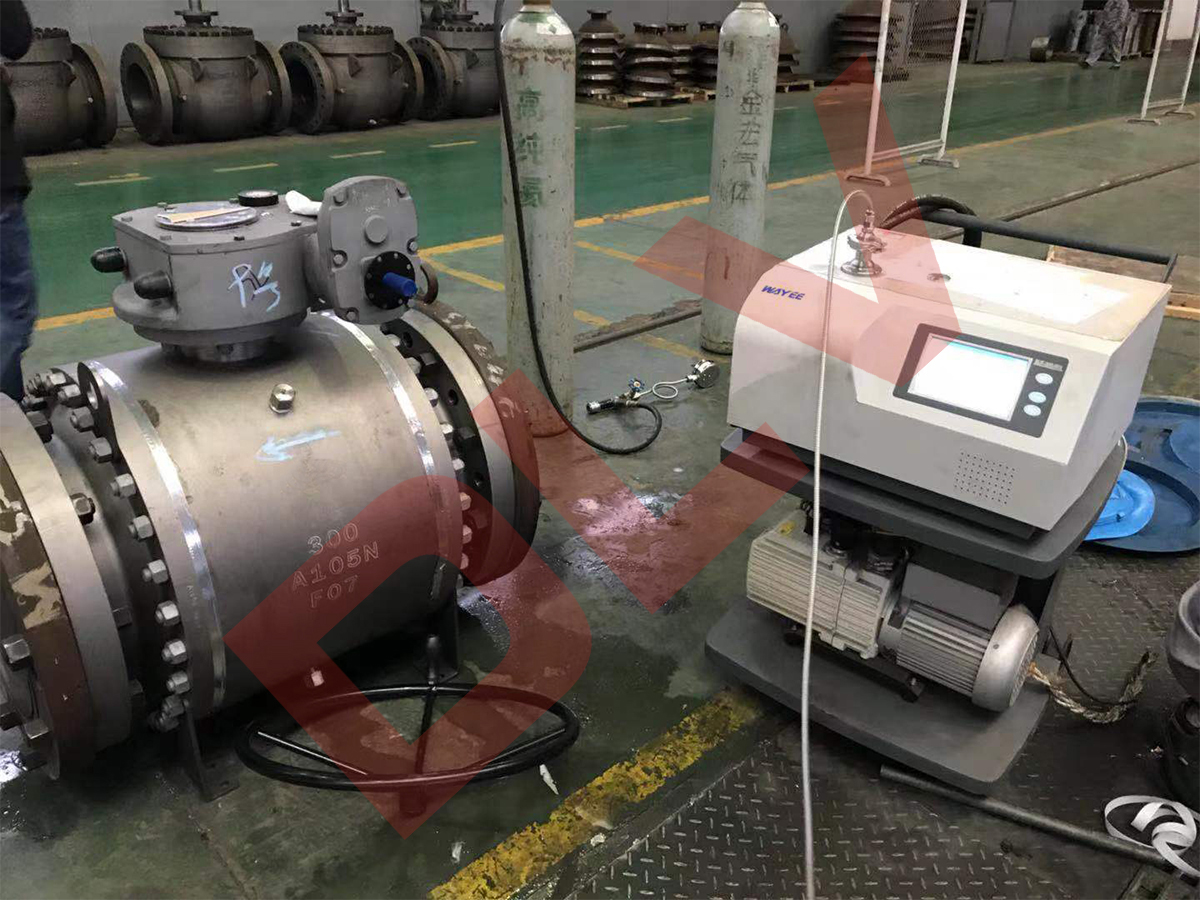

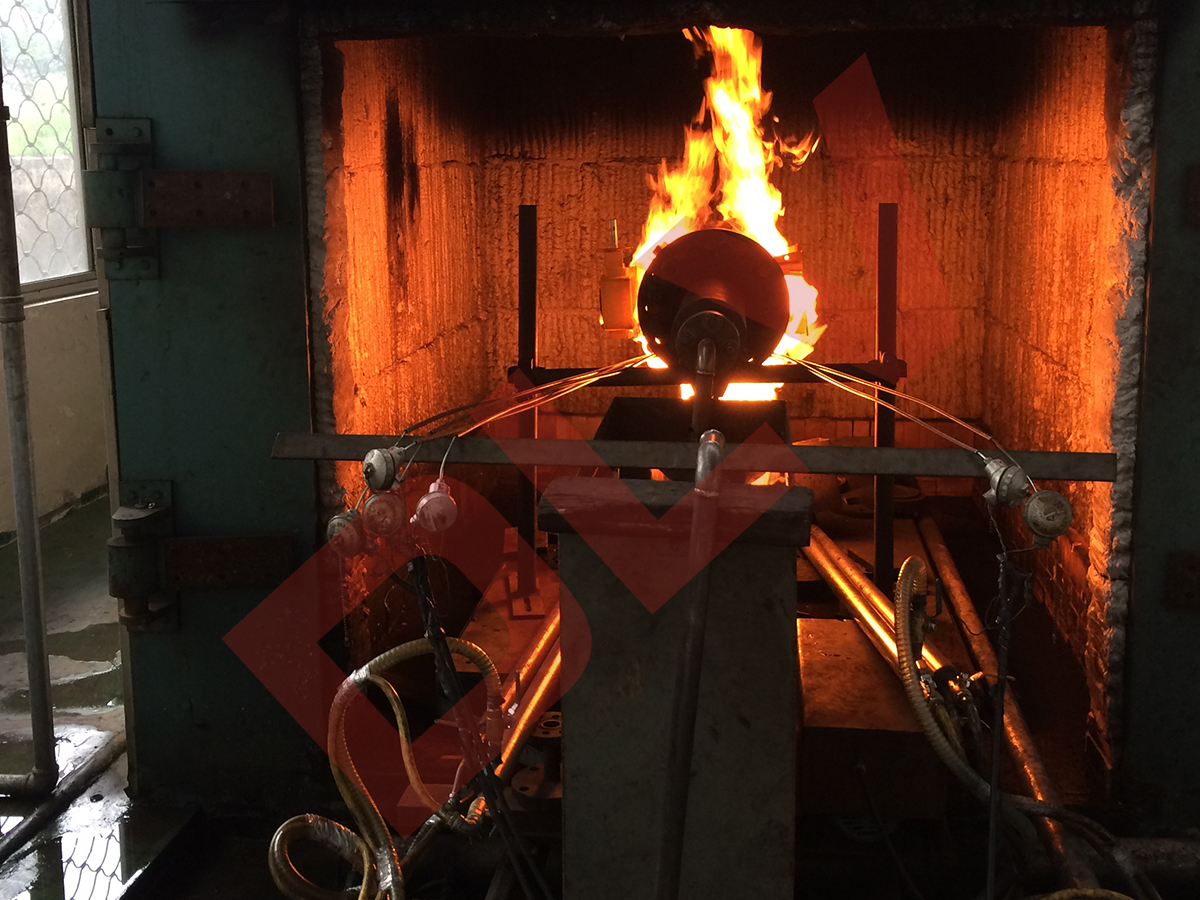

The manufacturing process of forged soft-sealed ball valves involves heating the metal to high temperatures and then applying pressure to shape it in a mold. This process produces a denser material with greater strength and stiffness. Cast soft-sealing ball valves, on the other hand, are produced by pouring molten metal into a mold and allowing it to solidify, which can cause pores and inclusions in the material. Therefore, the material uniformity and density of cast soft-sealing ball valves are worse than that of forged ball valves.

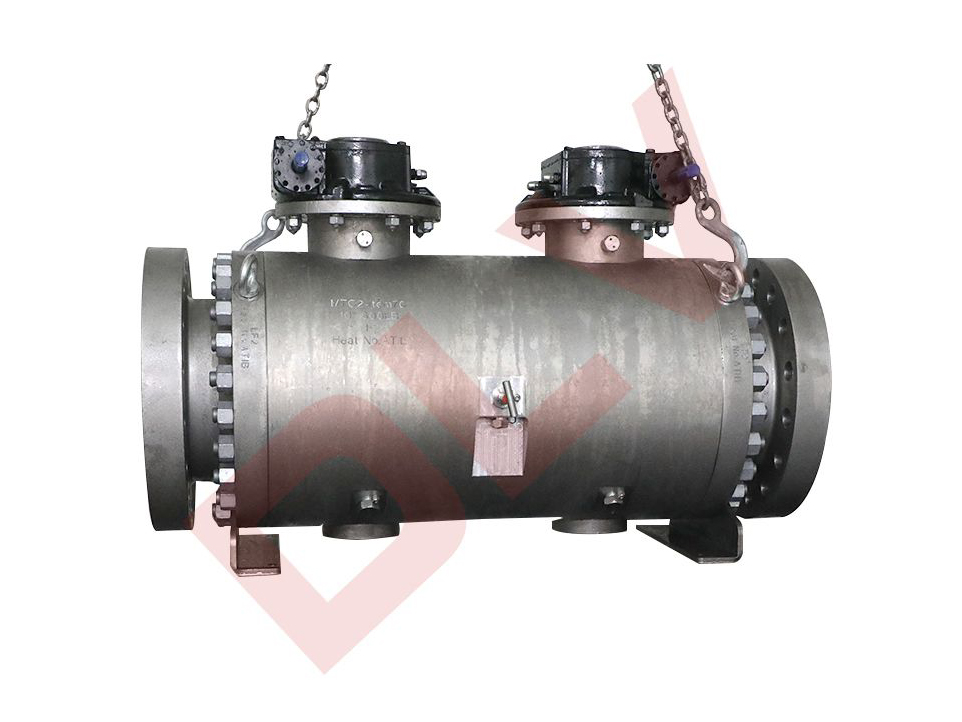

From the perspective of performance characteristics, forged soft seal ball valves are known for their high pressure resistance and wear resistance. This makes them suitable for use in harsh working conditions such as high pressure, high temperature, and highly corrosive environments. On the other hand, cast soft-sealing ball valves may be more suitable for operation under general operating conditions.

When selecting a ball valve, the manufacturing process and performance characteristics of forged and cast soft-sealed ball valves must be comprehensively considered based on the specific working environment and usage requirements. For applications where durability and strength are critical, a forged soft-seated ball valve would be the ideal choice. Conversely, for less demanding operating conditions, a cast soft-sealed ball valve may be sufficient.

The difference between forged soft-sealing ball valves and cast soft-sealing ball valves lies in the manufacturing process and performance characteristics. The former is produced through a process that produces a denser and stronger material, making it suitable for harsh working conditions, while the latter is more suitable for general working conditions. When choosing between the two, it is important to consider the specific requirements of the application to determine the most suitable product. Whether you need a ball valve for high pressure, high temperature, or corrosive environments, or just for general use, understanding the differences between forged and cast soft-seated ball valves will help you make an informed decision.