valves are connected in a variety of ways-supplement

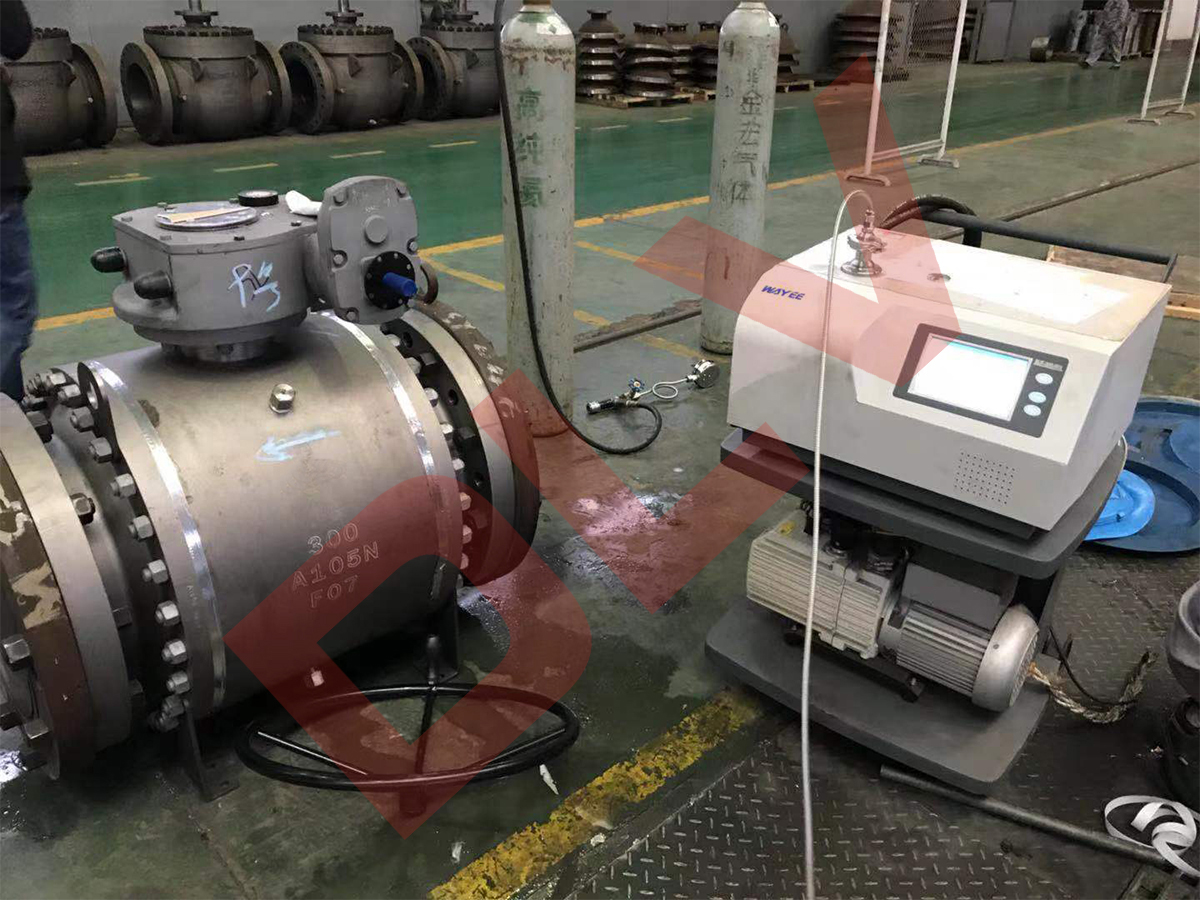

1. Flange connection

Advantages:

Strong connection, good sealing, suitable for valve connection under harsh conditions such as high pressure, high temperature and corrosive media.

Easy to disassemble and repair, easy to maintain and replace valves.

Cons:

The installation requires more bolts and nuts, and the installation and maintenance cost is high.

The flange connection is relatively heavy and occupies a large space.

Flange connection is a common valve connection, its standard mainly includes the following aspects:

Flange type: According to the shape of the connecting surface and the sealing structure, the flange can be divided into flat welded flange, butt welded flange, loose sleeve flange, etc.

Flange size: The size of the flange is usually expressed as the nominal diameter (DN) of the pipe, and the flange size may vary from standard to standard.

Flange pressure rating: The pressure rating of the flange connection is usually indicated by PN (European standard) or Class (American standard), and different grades correspond to different working pressure and temperature ranges.

Sealing surface form: flange sealing surface in a variety of forms, such as plane, convex surface, concave and convex surface, mortising surface, etc., should be based on the nature of the fluid and sealing requirements to choose the appropriate sealing surface form.

2. Threaded connection

Advantages:

Simple connection, easy operation, no special tools or equipment required.

Suitable for the connection of small diameter valves and low pressure pipelines, low cost.

Cons:

The sealing performance is relatively poor and it is easy to leak.

Only suitable for low pressure and low temperature conditions, for high pressure and high temperature environments, threaded connections may not meet the requirements.

Threaded connection is mainly used for small diameter valves and low pressure pipeline systems, and its standards mainly include the following aspects:

Thread type: Commonly used thread types are pipe thread, taper pipe thread, NPT thread, etc., should be selected according to the pipe material and connection requirements of the appropriate thread type.

Thread size: The size of the thread is usually expressed in nominal diameter (DN) or pipe diameter (inch), and the thread size may vary from standard to standard.

Sealing material: To ensure the tightness of the connection, sealing materials such as sealant or sealing tape are usually applied to the threads.

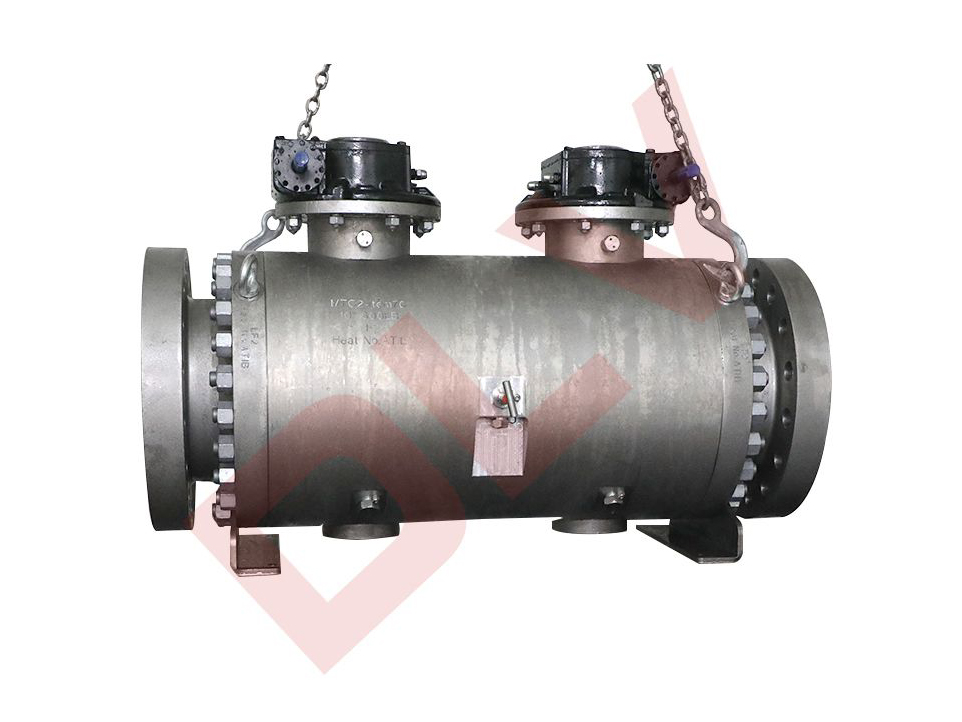

3. Weld the connection

Advantages:

High connection strength, good sealing, corrosion resistance, suitable for permanent and highly sealed occasions, such as petroleum, chemical and other industries of the pipeline system.

Cons:

Requires professional welding equipment and operators, installation and maintenance costs are high.

Once welded, the valve and pipe will form a whole, which is not easy to disassemble and repair.

Welded connections are suitable for scenarios that require high sealing and permanent connections, and their standards mainly include the following aspects:

Weld type: The common weld types are butt welds, fillet welds, etc., and the appropriate weld type should be selected according to the pipe material, wall thickness and connection requirements.

Welding process: The selection of welding process should be comprehensively considered according to the material, thickness and welding position of the base metal to ensure welding quality and connection strength.

Welding inspection: Necessary inspection and testing should be carried out after the completion of welding, such as appearance inspection, non-destructive testing, etc., to ensure the quality of welding and the tightness of the connection